Pavement Management

"The right treatment, on the right road, at the right time, with the right contractor, for the right price."

"The right treatment, on the right road, at the right time, with the right contractor, for the right price."

The City of Glendale’s Transportation Department is continuously working to improve and maintain its roadway network. Maintaining a strong network of streets is beneficial to everyone at the regional and local level for connectivity, safety and economic growth.

The current roadway network is comprised of approximately 770 centerline miles of roadway which is nearly 18 million square yards of asphalt and concrete surfacing. It is estimated that the average complete replacement cost for a major roadway is between $7.0-$9.0 million per mile. This indicates a very large amount of funding invested in pavement roadway networks nationwide and specifically within the City of Glendale. Given the high costs of reconstruction, it is imperative to maintain and extend the life of the existing pavement surface to the maximum extent possible.

The city has developed a Pavement Management Program (PMP) to best address street pavement needs. The American Public Works Association defines pavement management as a systematic method for routinely collecting, storing, and retrieving data and information needed to make maximum use of limited resources. The benefits of pavement management are numerous, including rational resource allocation, optimal use of funds, pavement rehabilitation cost reductions, pavement treatment selections, and pavement life extensions. A PMP will ultimately enable best practices for pavement needs that emerge over time.

Properly maintaining our City streets is a major task. As such, the PMP consists of the rehabilitation of poor and deteriorating streets within the City of Glendale with the application of common treatments as well as other innovative pavement preservation methods. The City of Glendale regularly evaluates the condition of roads and streets to assess the need for maintenance or repair, in addition to prioritizing and scheduling how this takes place. The plan to extend the overall life-expectancy of the City of Glendale’s streets through the most efficient and cost-saving measures is carried out through a series of pavement preservation strategies.

The PMP goal with currently available resources is to touch between 110-130 miles of Glendale streets per year in perpetuity.

Our PMP toolbox includes:

- Crack Seal

- Asphalt Rejuvenator

- Sealcoats (such as Polymer Modified Surface Seal)

- Slurry Seal

- Micro Seal

- Fractured Aggregate Surface Treatment (FAST)

- FAST + Sealcoat

- Cape Seal (FAST + Slurry or Micro Seal)

- Thin Overlay (1" to 1.5"); May be considered a "Partial Reconstruction"

- Mill & Overlay (1.5" plus); May be considered a "Reconstruction" to a "Full Reconstruction"

The PMP process includes identifying streets, respective treatment types, contractor scheduling, pre-treatment measures, and placement of the final surface treatment. It is a multi-dimensional undertaking. Construction activities are invariably not always going to occur as originally scheduled. Other factors include weather delays, equipment breakdowns, interruptions to material supply chains, unknown utility conflicts, commitments to other municipalities by the contractor, additional work/material required on streets ahead of other streets in queue, and to a lesser extent staffing resources.

Residents, businesses and travelers are typically notified of upcoming pavement applications or restoration via traffic control signage or individual mailers or door hangers, dependent upon the type and impact of the process to be conducted.

The City sincerely apologizes for any inconveniences and frustrations that occur due to delays or continued postponements. We are not always going to be perfect all of the time; but please rest assured that we do not take delays very lightly and make monumental efforts to bring activities back on track for a successful PMP implementation process. The lines of communication are always open and we encourage you to use them, but most importantly, we appreciate your support too!

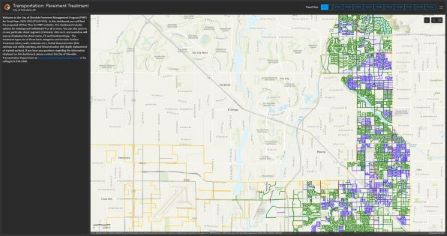

Current Project Map:(PDF, 4MB) A new map of areas to be treated between July 2025 to June 2026 is posted with specific surface treatments.

This updated Pavement Management Program map includes all coverage (approx. 134 miles) identified for the 2026 Fiscal Year.

A report has been developed that documents the state of our City street network with details pertaining to surface conditions, targeted Pavement Condition Index, and available and proposed budget amounts. Please select the following image to view the results of the of the current Pavement Management Program Plan and Citywide Street network pavement conditions.

(PDF, 57MB)

(PDF, 57MB)

In addition to the report above, a dashboard of the 10-Year Pavement Management Plan that includes all of the City street segments that will touched by the Plan has been created for your information. On it, you can zoom in on any street of interest and displayed will be the street name, its assigned Fiscal Year, and a general treatment category (Surface Treatment, Partial Reconstruction, or Reconstruction). Select the following image to launch the dashboard:

For more information on the City of Glendale’s Pavement Management Program, please contact our project hotline at 602.532.6250.

District Updates

Provided below are upcoming activities over the next week or two according to the contractor’s current schedule. Should you have questions or need information, please contact our 24/7 project hotline at 602.532.6250.

District Maps

City District maps are available below showing Pavement Management Program work anticipated to be completed by June 2026. Any remaining areas not completed are prioritized at the beginning of the subsequent fiscal year.

Please note that significant resources are being allocated to complete all areas within the stated timelines to provide Glendale residents with a positive and aesthetically pleasing driving experience.

Barrel District

Barrel District Fiscal Year 2026 PMP Work(PDF, 613KB)

Upcoming Work Scheduled

-

Royal Palm Road, between 59th Avenue and 63rd Avenue – Thin mill and overlay to take place in early 2026.

-

61st Avenue, between Royal Palm Road and Olive Avenue – Thin mill and overlay to take place in early 2026.

-

Alice Avenue, between 59th Avenue and 67th Avenue – Thin mill and overlay to take place in early 2026.

-

Streets between Mountain View Road and Peoria Avenue, between 51st Avenue and 55th Avenue – Crack sealing is currently taking place to prepare for a Slurry Seal application to take place later in the program.

-

Peoria Avenue, between 51st Avenue and 67th Avenue – Crack sealing to begin December 1 to prepare for Slurry Seal application to take place later in the program.

-

59th Avenue, between Olive Avenue and Cactus Road – Crack sealing to begin December 8 to prepare for Slurry Seal application to take place later in the program.

-

Olive Avenue, between 59th Avenue and 67th Avenue – Crack sealing to begin December 8 to prepare for Slurry Seal application to take place later in the program.

-

Peoria Avenue, between 51st Avenue and 59th Avenue – Crack sealing to begin December 15 to prepare for Slurry Seal application to take place later in the program.

-

Streets between Royal Palm Road and Olive Avenue, and between 59th Avenue and 61st Avenue – Crack sealing to take place in mid-January to prepare for Slurry Seal application to take place later in the program.

-

Streets between Butler Drive and Olive Avenue, and between 63rd Avenue and 67th Avenue – Crack sealing to take place in mid-January to prepare for Slurry Seal application to take place later in the program.

-

Streets north of Royal Palm Road to Echo Lane, between 61st Avenue and 63rd Avenue – Crack sealing to take place in mid-January to prepare for Slurry Seal application to take place later in the program.

-

Townley Avenue, west of 61st Avenue – Crack sealing to take place in mid-January to prepare for Slurry Seal application to take place later in the program.

-

Residential streets between Cholla Street and Cactus Road, between 59th Avenue and 67th Avenue – Crack sealing is currently taking place to prepare for Slurry Seal application to take place later in the program.

Cholla District

Cholla District Fiscal Year 2026 PMP Work(PDF, 650KB)

Upcoming Work Scheduled

-

Lone Cactus Drive, just west of Arrowhead Loop Road and 61st Avenue, just east of Arrowhead Loop Road – Mill and overlay to take place in mid-January.

-

Rose Garden Lane, Lone Cactus Drive and 61st Drive, just east of Arrowhead Loop Road - Mill and overlay to take place in mid-January.

-

Streets north of Beardsley Road to south of Thunderbird Conservation Park, between 59th Avenue and 67th Avenue (excluding streets recently resurfaced or currently scheduled for mill and overlay) – Due to cooler daytime temperatures setting in, the remainder of the slurry seal application has been postponed to Spring 2026 when warmer weather returns.

-

Streets between Union Hills Drive and Beardsley Road, and between 75th Avenue and the Loop 101 – Crack sealing to begin in early January to prepare for a Latex Modified Surface Seal (LMSS) application to take place later in the program.

Ocotillo District

Ocotillo District Fiscal Year 2026 PMP Work(PDF, 525KB)

Upcoming Work Scheduled

-

Streets from Maryland Avenue to Ocotillo Road, between 59th Avenue and 67th Avenue – Crack sealing to take place in mid-December to prepare for Slurry Seal application to take place later in the program.

-

Streets between Bethany Home Road and Maryland Avenue, and between 67th Avenue and 75th Avenue (excluding streets west of 74th Avenue, south of Rose Lane) – Crack sealing to take place in late January to prepare for Slurry Seal application to take place later in the program.

-

Streets from Maryland Avenue to south of Ocotillo Road, between 71st Avenue and 75th Avenue – Crack sealing to take place in late January to prepare for Slurry Seal application to take place later in the program.

-

Ocotillo Road, between 67th Avenue and 71st Avenue – Concrete repairs are currently taking place in advance of a mill and overlay to take place later in January.

Sahuaro District

Sahuaro District Fiscal Year 2026 PMP Work(PDF, 2MB)

Upcoming Work Scheduled

-

Michigan Avenue, west of 59th Avenue to west of 61st Avenue – Concrete repairs to begin December 1 in advance of a mill and overlay to take place later in January.

-

Peoria Avenue, between 51st Avenue and 59th Avenue – Crack sealing to begin December 15 to prepare for Slurry Seal application to take place later in the program.

-

Streets between Thunderbird Road and Acoma Drive, between 51st Avenue and 55th Avenue – Crack sealing and asphalt repairs to begin December 1 to prepare for a Latex Modified Surface Seal (LMSS) application to take place later in the program.

-

Streets between Greenway Road and Paradise Lane, from the 67th Avenue frontage road to 65th Avenue – Asphalt repairs to take place this Fall to prepare for a Cape Seal to take place later in the program.

-

67th Avenue frontage road, on the west side of 67th Avenue, south of Paradise Lane – Asphalt repairs to take place this Fall to prepare for a Fractured Aggregate Surface Treatment (FAST) as a base coat with Latex Modified Surface Seal (LMSS) application as a top coat to take place later in the program.

Yucca District

Yucca District Fiscal Year 2026 PMP Work(PDF, 626KB)

Upcoming Work Scheduled

-

Glen Harbor Boulevard, between Glendale Avenue to WAWRF – Crack sealing to begin November 20 to prepare for a Latex Modified Surface Seal (LMSS) application to take place later in the program.

-

Streets between Glendale Avenue and Orangewood Avenue, from 81st Avenue to east of 83rd Avenue – Crack sealing and asphalt repairs to begin December 11 to prepare for a Latex Modified Surface Seal (LMSS) application to take place later in the program.

Pavement Preservation Ordinance

The City of Glendale adopted a Pavement Preservation Ordinance, Ordinance No. 021-73 in October 2021, that governs the use of streets and public rights-of-way in order to preserve street pavements. The Ordinance seeks to preserve pavements by restricting cuts and excavations in pavements that have been recently resealed, constructed, reconstructed, or resurfaced. In an effort to ensure street pavements are preserved, the department seeks permittees to coordinate their pavement cuts with the city so that all work is done simultaneously, and the pavement is not excavated or cut more than once within a twelve-month period, and (in accordance with Sec. 30-83) not within two (2) years after completion of street construction, reconstruction or renovation.

If you are an entity that requires a pavement cut along any Glendale maintained street, please follow the process.

Frequently Asked Questions

What is a Cape Seal?

A Cape Seal consists of an application of Fractured Aggregate Surface Treatment (FAST) as a base course, covered in an application of Slurry Seal.

There are several steps involved for a Cape Seal, as follows:

- Crack sealing, as necessary. Cracks are primarily sealed only in the center of the roadway because the cracks nearest the curbs will be addressed as part of another step (below).

- Next, crews will remove and replace corner sidewalk ramps to bring them into compliance with the Americans with Disabilities Act (ADA). Residents will receive a postcard prior to this activity. During this time, crews may also remove and replace valley gutters adjacent to the ramps, as needed. Valley gutters are concrete gutters which run parallel to the roadway to assist drainage in flowing across side streets. To accommodate this work, there will be brief road closures while crews remove the existing valley gutter and install the new valley gutter. Following the concrete installation, there will be small strips where the asphalt has been removed adjacent to the newly installed concrete ramp or valley gutter. These strips will be temporarily filled with loose aggregate that will be compacted until the asphalt is permanently patched in the next step.

- Asphalt patching and repairs will take place in miscellaneous areas and also along newly installed concrete.

- Crews will mill (remove) asphalt along the sides of the road closest to the curb lane to lower the profile of the road to avoid creating a lip at the curb when the surface seals are applied. Immediately following the milling, crews will apply FAST. Residents will receive a door hanger on the front door of their home prior to this activity. FAST is comprised of asphalt rubber and fractured rocks which will be put down as a base coat. This application will also act as a sealant to the cracks closest to the curb lane. FAST is typically applied to one-half of the road at a time to maintain traffic and it cures relatively quickly so traffic can usually resume within a couple of hours. Some sloughing, or small loose rocks, on the roadway is expected and will be minimized by the final seal in the next step.

- Following the FAST application, crews will apply a slurry seal. Slurry seal is also typically applied to one-half of the roadway at a time to maintain traffic; however, it does have a longer cure time. Residents can expect one-half of their street to be closed to traffic between 7 a.m. and 5 p.m. Residents will typically receive another door hanger on the front door of their home prior to this activity because this slurry seal application takes place sometimes up to weeks after the FAST application. In the event the slurry seal application is following the FAST application more quickly, than the information for both may be included on one door hanger which is distributed prior to the FAST application.

- Once the seals have been completed, utilities, such as manholes and valves, may need to be raised to make them flush with the roadway, striping will be reapplied, and the pavement application complete.

For all of these activities, on-street parking may be restricted and No Parking signs will be placed 48 hours in advance if that is the case. Residential services, such as trash and postal, should not be impacted by this work. Traffic control will be in place to protect the work area so please do not drive across fresh sealant until traffic control has been removed. Additionally, please do not allow water to run into the streets 48 hours prior to work taking place since the sealants will not adhere to wet asphalt.

How will I know when my street is scheduled?

Generally speaking, mailers go out to affected areas as preparatory work begins (i.e., crack seal and concrete/asphalt repairs), and this is followed by door hangers for surface seal applications.

What if trash or bulk trash pick-up is scheduled the same day?

The contractor is required to coordinate with Glendale Sanitation so set your trash out by 7 a.m. if work is scheduled on your regular trash pick-up day.

What about postal services?

Postal services should not be affected.

What about on-street parking?

On-street parking will not be permitted during the application and “No Parking” signs will be posted a day or more in advance of the work to ensure vehicles are off the street for the application to take place.

Can I get out of my garage/driveway?

The door hanger you will receive will provide specific information, and please be sure not to drive through barricades or traffic cones as they protect the contractor’s work area.

What happens if work does not take place or is delayed?

In some cases, such as inclement weather (rain) or materials/scheduling issues, work may need to be adjusted. Unless your notification says otherwise, work will be moved to the next possible working day and you may or may not be notified again. Please keep the information you receive until the work in your area has been completed.

Surface Seal Applications

For roads that require preventive maintenance or in which pavement sections are in generally average or above average condition, many topical applications are available which extend the life of the pavement for many years. Typically referred to as “slurry seal”, this application may include different varieties and timing or applications. Glendale currently uses slurry seal; double slurry seal (which makes two passes across the asphalt pavement over a specific time period); sealcoat (polymer-modified surface seal); or FAST (fractured aggregate surface treatment) for their surface seal applications. These applications are topical, with a coating being applied to the existing surface of the street and when needed, this effort is typically preceded by asphalt repairs or a crack seal application. Streets crews assess each street prior to a pavement treatment and identify areas for concrete or asphalt repairs, or crack sealing.

Concrete/Asphalt Repairs

These require the removal of a smaller section of concrete or asphalt by lining out, saw cutting and removing the material, followed by replacement of new concrete or hot asphalt and compacting as necessary to provide a quality end product. For concrete repairs, asphalt surrounding the newly placed concrete is typically placed back after the concrete cures.

Crack Sealing

Inspection staff and the contractor will identify nominally large cracks in the existing pavement, or those which pose a future risk to the integrity of the asphalt. Once identified, crews apply a sealant directly on or over the crack to prevent further degradation or water entering the crack which may impact the subsurface of the roadway and create greater issues in the future.

Once repairs and crack sealing are completed, the surface treatment application can take place. Crews may first remove any thermal striping that may exist on the roadway, and then apply the surface treatment. Equipment typically is wide enough to cover 1 to 1 1/2 lanes of roadway, so this usually requires several passes of the application to cover the entire roadway. Generally speaking, roads typically remain open for travel during this process; however, traffic is shifted away from the work zone and left turns may be restricted so that vehicles do not travel over the fresh application. As the treatment crosses in front of side streets and driveways, there may be brief period of time where access may not be permitted (15-30 minutes). While this may be frustrating during the process, it is important to the quality of the application that vehicles do not immediately travel over it. Construction crews typically direct travelers and, once complete, unobstructed travel may resume. Once the surface application is complete, the road can be restriped and any valves or utilities adjusted to be flush with the road surface, if necessary. For areas that require thermal striping, this is usually applied 30 days after the application has taken place.

Mill and Overlay Applications

For roads that are in greater need of repair, a mill (removal of asphalt) and overlay application is typically conducted.

Sidewalk ADA (Americans with Disabilities Act)

Ramps and Concrete Repairs

Completed to ensure compliance with ADA and safety standards. Prior to pavement treatment, ADA ramps are removed and replaced or newly installed, valley gutters may also be replaced or newly installed, and any sidewalk or curbing may be determined to need replacement. Valley gutters are the concrete gutters that typically run across the street, designed to carry storm water across the roadway to a nearby catch basin or storm drain. Concrete work typically takes place in the public right-of-way and landscape disturbed during this process is restored or adjusted, if needed to retrofit the new ADA ramp. For the best quality pavement application, this concrete work needs to take place prior to any pavement treatment.

Valve/Utility Adjustments

Completed first to prepare for the milling process. Valves and utilities that exist in the roadway to be milled are lowered below the surface of the asphalt so that they are not damaged during the asphalt removal. Once the mill and overlay process is complete, they are raised once again to be flush with the new asphalt surface. When work will take place near a signalized intersection, it may be necessary to also remove or replace traffic signal loops, which are placed in the asphalt pavement at the approaches to the intersection and detect vehicles wanting to enter the intersection; this triggers the traffic signal to cycle through.

Mill and Overlay

The mill and overlay process can then begin, first with crews milling (removing) a predetermined measure of asphalt (1” or greater) dependent upon the condition of the existing asphalt. Equipment typically is wide enough to cover 1 to 1 1/2 lanes of roadway, so this usually requires several passes of the milling machine to conduct the removal. Generally speaking, roads typically remain open for travel during this process; however, traffic is shifted away from the work zone and left turns may be restricted. As this process crosses in front of side streets and driveways, there may be brief period of time where access may not be permitted (15-30 minutes).

Once the milling is completed, crews can apply the new asphalt surface and conduct any compacting of the asphalt. Once again, this takes place typically with several passes of the paving machine and, at times, access may be restricted as the machine crosses side streets and driveways. While this may be frustrating during the process, it is important to the quality of the final product that vehicles do not immediately travel over the new asphalt surface until it has cooled slightly. Construction crews typically direct travelers and, once complete, travel may resume. Once the paving is complete, the road can be restriped and any valves or utilities raised to be flush with the road surface. For areas that require thermal striping, this is usually applied 30 days after the application has taken place.

Notifications

Residents, businesses and travelers are typically notified of upcoming pavement applications or restoration via traffic control signage or individual mailers or door hangers, dependent upon the type and impact of the process to be conducted.